Studying new abilities and getting the seat carried out.

I´m going inventory, 530. It doesn’t matter what, I´m making an attempt to recreate the look the bike had when “Esso” received the Swedish GP 1970. Which means 530. I´m fairly certain he didn´t alter the chain till a lot later, if he ever did in any respect.

So, I opted for the 530 sprocket and had it mounted to the rear wheel. In fact I had managed to unfastened one of many nuts. I discovered a batch of NOS ones on eBay and received them residence. Any day now I’ll discover the misplaced one, I often do…

I´ve been trying on just a few YouTube movies on the best way to safewire bolts and nuts. It appears to be a sophisticated activity in case your utility calls for excessive safety like on plane elements, propellers and many others. Right here it’s not so vital. The target is to maintain the nuts from turning unfastened throughout driving on a racetrack. I can try this…..

I discovered just a few completely different patterns to make use of relying on what number of nuts you have to safe. I made a decision to go together with the “Two-nut” methodology and prolong it to my 5 nuts. The thought is to create a wiring that’s tensed within the appropriate path to carry the nuts in place in relation to one another. The beginning is made with sufficient wire to go across the 5 nuts and positioned midway by the primary nut.

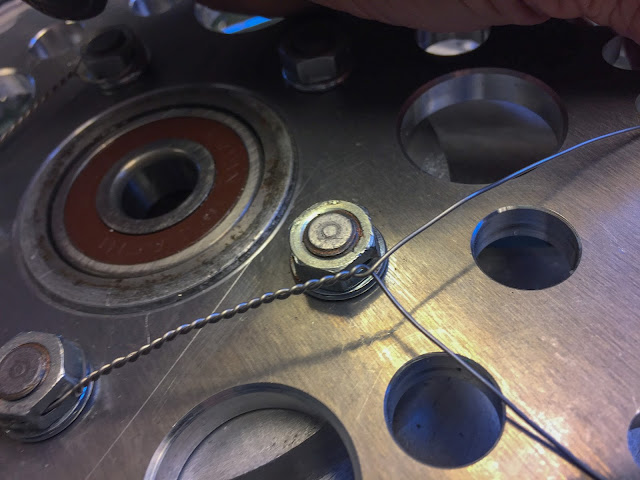

I´m slowly working my manner across the nuts making an attempt to get the wire as tight as attainable between them. The “How-to-videos” typically describe how it’s best to put the wire round each nut, however I discovered that pointless on those between the primary and final. Proper or improper? I don´t know. So long as the nuts can´t transfer I´m glad. The instrument is an easy security wiring instrument known as “Wapid Wiring instrument” Low cost, not so good, however it does what it´s presupposed to…

Right here on the left, you may see the “appropriate” method to route the wire on the nut to the left within the image. Subsequent I’d take the decrease piece of wire and go around the nut, the upper goes by the opening within the nut and joins the decrease on the opposite aspect. Then I’d proceed turning them in direction of the following nut.

Right here´s what I did as a substitute. In my world this secures the nut simply nearly as good. Seems higher to me, in order that´s the best way it was carried out on the final nuts.

And Voila´, right here´s the completed consequence. I do know it´s not good in any manner however it´s my first attempt at it. The subsequent time I´ll be higher and know barely extra on the best way to do it. I imagine the final pressure of wiring between the final and again to the primary nut, as an example, is pointless. They’re each locked to the second and fourth nut respectively. But it surely appears to be like higher with an entire circle, although.

The subsequent activity was getting the rear wheel again on the bike. Final time I did this it went surprisingly easy… Not so this time! I´m off to a superb begin right here with the rear axle, chain tensioner and the spacer in place for the wheel to be lifted up. Up to now so good!

Bought the opposite spacer, the brake plate and the suitable hand chain tensioner in place and the axle went by simply superb. Wheel turned, no hick-ups… Till I checked the clearance between the sprocket bolts and the swing arm/chain tensioner. Now, That´s Shut!

And right here´s the reply. They’ve been involved. I vaguely keep in mind pondering these tensioners didn´t appear to be they do in lots of eBay listings or in my elements guide. There they’re easy, no pressings on the aspect like these have. Why didn´t I’ve hassle with this the final time?

And the reply is right here! One in all them has been altered… By merely hammering that urgent out to make it easy. You’ll be able to see that tensioner right here on the left. I had merely put them on the “improper” manner round. OK, somebody argues… Get NOS ones! Yeah, I would try this, however for now these must do. AND, they had been on the bike, they’ll do their job, so I would simply hold´em!

And right here´s the one occurring the suitable hand aspect of the bike the place there´s no sprocket bolts to intrude with the tensioner. Discover how there´s a built-in washer with an index on the skin of the tensioner? That´s to have the ability to modify the wheel straight within the swing arm to accurately line up the 2 sprockets.

The subsequent challenge was to drill some used, however very good M10 X 1,25 engine mounting bolt nuts from a avenue H1-69 I had in inventory. the nuts used on the racer had been in as dangerous nick because the lengthy bolts. Not adequate. That is one other factor I had by no means tried earlier than. Drilling with such a small drill bit (1,5 mm) is a fragile factor. First I attempted a 2 mm one. I broke it off on the first attempt. Hmm, higher be extra mild. The laborious half right here is beginning the opening at a 90 diploma angle after which regularly, with out braking that friggin´delicate drill bit, altering the angle so it drills the opening from one flat floor to the opposite and never straight by to the threads.

One thing like this! A pleasant gap to safe the nut with. Discover these M10 nuts are fairly small in socket or key dimension. Not a lot materials to drill in. I believe they are going to be good for the racer regardless that they got here from a avenue bike. On the H2:s there are particular “locking nuts” used to suit the engine to the body. I might have used a few of these, however I don´t assume they had been used till 1972 so they’d be improper right here…

It took some time, however right here they’re. 3 for the bigger bolts underneath and on the entrance of the engine and two for the higher, rear mount. As you may see I didn´t get them to look precisely the identical. Every drilling was a taking place, to say the least!

No washers on the bolt head aspect. Unusual, however that´s the best way it’s presupposed to be. One lock washer per nut on the opposite aspect. In fact I had forgotten one of many rear bolts is an M8… Additionally a distinction from the road bikes the place each bolts are M10. Ergo, I had the pleasure of drilling an M8 nut as nicely!

I can´t assist pondering it´s humorous the best way they use rubber washers as some form of vibration damping methodology…

If it really works? I don´t know. The engine for certain isn´t “rubber-mounted”, it simply has some rubber washers between the metal elements. Unusual. Nicely, as I used to be tightening these two I needed to plan for the protection wiring. You need the securing to be efficient and the best way to perform that’s this….

The twisted a part of the protection wire is routed at an angle that secures each nuts to one another. Think about the decrease one loosening. Which means the wiring is tightening the highest nut more durable and vice versa. I do know it might have been extra tense, however I´m getting there! It is a type of artwork. Takes time to grasp it, however I’ll get higher. I Must! The remainder of the engine bolts and their security wiring needed to wait till I received again from work.

As I did that a few days in the past I had been involved with Janne and he requested how my seat was progressing. He had tried to lock the push buttons with instruments of his personal and made a multitude of your entire challenge. I simply needed to attempt it… With the suitable instrument!

Right here´s the deal… The 2 elements on the left is riveted collectively by the quilt materials and the one on the suitable is riveted or screwed in to the fiberglass seat. Simple? Yeah, in principle.

Right here´s the important thing to success. The particular “riveting, push button instrument” It may be rented per hour or day from most boating provide shops that promote canopies and many others. The place the place I purchased my push buttons had it…

First you have to work out what urgent socket to make use of within the instrument. Right here I’ve them lined-up to attempt to perceive which one to make use of. In fact I had all of it improper, as you would possibly discover. So my first press was an utter failure. The items fell aside directly. I had chosen the improper socket…

Earlier than beginning to press the buttons collectively I attempted to plan the best way to do it finest. The best push buttons to put completely appropriate was the 2 up entrance. They’re near the sting and the quilt can actually sit solely in a technique across the entrance edge. A very good start line!

OK, received them measured up and the holes made. The instrument is a “press-once-and-you´re-done” form of machine that makes it simple to do an skilled job! When you get the buttons in the suitable spot, you may´t actually go improper. Tremendous sturdy and prime quality instrument. Being a instrument fetishist I wouldn´t thoughts proudly owning one among these in any respect.

Right here, on the underside, you may see how the instrument “rolls” the sting of the highest a part of the push button in direction of the underside half and makes a powerful “rivet”. Tremendous good!

The entrance a part of the quilt matches properly. I assumed I must make the spherical “cutouts” a bit bigger however that is probably not needed. We´ll see in a while. Pär made the covers in order that it’s attainable to regulate these with out destroying any appears. Good pondering and excellent craftsmanship!

I often attempt to fasten any seat cowl I work on entrance and rear first after which work my manner across the edges stretching the quilt evenly on both sides. Now I wanted to determine the middle level of the highest rear a part of the quilt and have it positioned in a manner that might enable eradicating the rubber lid over the oil tank gap. Fortunately the quilt has appears that inform precisely the place the center a part of the quilt is. Simple to carry it in place and mark the holes for the rivets with a ball level pen.

“No guts, No Glory” Right here we go! Now that the quilt is on on the entrance and rear it’s simple to work your manner across the edges, one button at a time, symmetrically, consistently checking for every thing to be straight and degree.

Every gap was made with with my leather-based gap punch instrument. It has plenty of completely different diameters and I attempted to make use of as small holes as attainable. You need the buttons to rivet tightly in to the fabric. I imagine I used a 3 mm punch for the 4 mm rivets…

To the left is the primary check out of the quilt. This time with none upholstery. It matches tight, however I believe it´ll be good when it has been on there for some time and in addition full of the rubber foam.

The results of an hours work! I´m more than happy. The lease for the instrument was negligible and intensely nicely spent cash.

From one other angle. The rubber cap is definitely eliminated and the best way the buttons cross the appear across the cowl is strictly the identical as on the unique one. The quilt is made to suit tight so each mm was wanted to get it on in any respect.

That is the quilt I´ll be utilizing on the bike if/once I´ll ever attempt it. The unique one will probably be used on show. Pär beneficial I’d deal with the leather-based with a dubbin, a moisturizer for leather-based ware. I had just a few manufacturers to select from however he really stated that abnormal Vaseline can be adequate.

It received a few shades darker and extra maroon in coloration when handled. I prefer it so much! I´m tremendous pleased with the seat up to now. I´ll repeat the remedy with Vaseline the approaching weeks and in addition get the seat completely fixed to the bike.

I do know the colour of the seat covers had been black again within the day, however I would like to search out some private issues to make the bike mine as nicely. This was a simple method to go about it.

Now it´s time to verify the journey top and modify the rubber cushions underneath the seat. Right here on this image I’ve none of them in place. I believe it appears to be like actual good this fashion. Possibly I´ll go for half of the rubbers. We´ll see…

So, that is what it appears to be like like proper now within the storage. It’s coming collectively properly. Subsequent is the everlasting fastening of the seat and to attempt to manufacture a clamp for the (actually small and silly) chain cowl on these bikes. Janne had two of these covers made, one for him and one for me… However I additionally want the clamp, 36024-003, if anybody has one laying round?!

That´s all for now… I´ll be again when some progress price writing about has been carried out on the bike. Till then:

Keep heat and get these bikes prepared for spring!

/Per

The post Studying new abilities and getting the seat carried out. appeared first on lickscycles.com.

source https://lickscycles.com/studying-new-abilities-and-getting-the-seat-carried-out/

No comments:

Post a Comment