Two-strokes are one thing which have all the time been in my blood. Rising up, each bike I owned was a two-stroke, and extra particularly a Yamaha. I had owned a number of YZ250s by means of my youthful days, as I all the time liked the flexibility of them being a greater than succesful bike in each the bush and on the observe, so it was an ideal bike for me!

As I acquired older although, it was changing into extra obvious that the necessity for one thing rego’d was going to be a necessity if I used to be to maintain driving the bush and hold myself out of bother. To not point out making life simpler, by not loading up a motorcycle every journey. So, the mind was ticking about what was subsequent and the obvious option to me was going to be the WR450F. Not wanting to surrender the two-stroke heritage although, there have been some critical ideas about leaping the fence to make the most of the 300cc two-stroke enduro fashions of different manufacturers. I had much more critical ideas about why on the planet Yamaha wouldn’t hurry up and soar on the 300cc two-stroke prepare, so I could possibly be first in line for one! That is actually the place the WR300 (or 325 because it was) thought was born.

THE FOUR-STROKE BUG

I had lots of expertise changing Honda CRF frames to re-home CR500 motors by means of my enterprise, Camesco Fabrications, for associates and clients. So, I knew the challenge was doable, however I actually wanted the WR in entrance of me to make all of the measurements and create an inventory of precisely what was wanted to make the dream come alive. So, the choice was made, I might hold the 250 for now and purchased the WR. The primary four-stroke I had owned and man what a luxurious! Heaps of torque, it tractored up something, clean energy supply, actually I liked it a lot that the entire 300 challenge almost didn’t come to fruition!

However there was nonetheless one thing lacking that I may by no means put my finger on, till someday, the chance arose to swing the leg again over the 250, and there it was.

PROJECT 325

The 325 challenge was now in full swing. I spent the subsequent 12 months or so measuring and remeasuring, sketching up design concepts, and accumulating components from everywhere in the globe. I needed to guarantee that each doable situation was labored out earlier than I even loosened a bolt, as I nonetheless needed a motorcycle to journey within the meantime, so I made certain to have all of the components I wanted to make the construct as seamless as doable.

The primary half we sourced was the large bore package. There’s a number of available on the market however after a little bit of analysis and talking with some individuals with first-hand expertise, the 325 large bore package by Eddie Sanders Racing was chosen as the brand new top-end. On the time, this was fairly exhausting to supply from ESR themselves (as covid was in full swing), however I used to be fortunate to have a contact within the big-bore group who put me in contact with a personal sale within the states. The deal was achieved, and it was starting to really feel a bit extra actual with the components on the best way.

Nonetheless considering power-plant, and the one factor I knew was important in making this challenge the bush weapon it needed to be, was the extensive ratio gearbox (wouldn’t be a WR with out it) which comes within the YZ250X however sadly not in the usual YZ motor, I had. Fortunately, I discovered that Rocky Mountain ATV sells a Yamaha extensive ratio transmission package that comes with third, fourth and fifth gears from the 250X, in addition to all the pieces else that you must convert it over. Retaining the unique 1st and 2nd gears and saving us the trouble of needing to supply all of the components individually, this package was a god ship.

SPARKY START

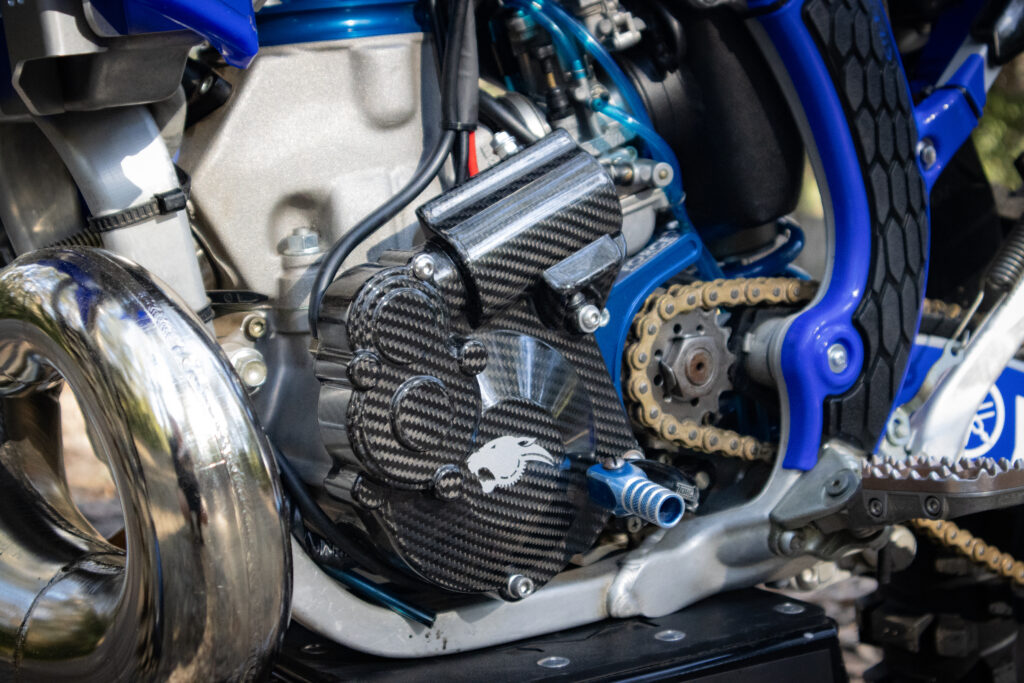

One other main element, and what I discovered to be essentially the most polarising a part of the entire construct, was the electrical begin. After spending lots of time on the WR, I knew there was no going again to the kick begin for me. Not solely that, however with out the electrical begin it simply didn’t full the imaginative and prescient of what I dreamt the WR325 can be if it was launched commercially. And let’s be sincere, after I’m caught on the facet of a rocky, slippery hill facet the very last thing I would like in my thoughts is ‘how I’m going to kick this factor again into life’. The Panthera Motorsports YZ Electrical begin package is one which has had combined critiques and been the topic of lots of discussions on on-line platforms, however with out another choices available on this class, warning was thrown to the wind!

On arrival, we had been blown away by the construct high quality and engineering concerned in placing this package collectively. The machined components all match completely, and it was really one of many best components to suit of the entire construct. After a brief quantity of testing, we discovered no faults with any of the mechanical workings of the electrical begin and it has gotten me out of multiple sticky state of affairs already!

Now, with all the most important engine elements in our palms it was time to tug the YZ engine out of the body. From right here, it was straight over to Greg James Bikes to be fully pulled down for a ground-up rebuild. Whereas we had the instances stripped, I took the chance to have all of them vapour blasted again to their authentic magnificence. Nothing was left untouched within the rebuild, in addition to including the brand new elements that had been not too long ago acquired. We lastly had the guts of the construct accomplished and it was the WR’s flip.

THE POINT OF NO RETURN

As we stripped down the WR to a naked body, the fact set in that this actually was the purpose of no return. Although all of the calculations had been achieved and it was now time to place the plan into motion, there have been nonetheless some issues that we couldn’t actually know till we acquired into it. Like all earlier conversions we had achieved which concerned placing a two-stroke engine right into a four-stroke body, we knew there would have to be a ‘Y’ piece added to the entrance part of the body to supply clearance for the enlargement chamber to cross by means of. Drawing inspiration from our CR500 conversions we contacted the crew at CP500 (conversionparts500.com) for some recommendation. These guys produce a few of the highest high quality conversion components that now we have ever used, together with some superior billet ‘Y’ items for his or her 500 builds, so we thought who higher to ask.

Inside an e-mail forwards and backwards, we had each dimensioned drawing for all of the ‘Y’ items they manufactured and after fastidiously wanting over each, we discovered one thing that we thought we may make work. This half alone made our job 100 occasions simpler and I can’t thank them sufficient for being fully open to sharing their information with us to get us this resolution.

With the primary main hurdle of the body work cleared it was time to make the primary cuts. I may solely put it right down to some strong preparation for this present day (perhaps a little bit of luck) but it surely was clean crusing at this level. Inside a day we had the ‘Y’ piece fitted, new decrease engine mounts fabricated and eventually a have a look at the brand new coronary heart sitting completely in its new residence. Nearly too completely! Every thing appeared to line up, the angle, the heights, the spacings, prefer it was simply meant to be. This was an important motivation for the subsequent steps as we knew we weren’t out of the woods simply but. From right here the top keep mounts needed to be manufactured with a brand new crossmember added inside the body to help a inventory type bracket which we had laser reduce with our emblem in it. We spent lots of time attempting to make issues look as manufacturing unit as doable with an general aim of a ‘straight off the showroom ground’ look that we had been going for. These items accomplished the engine mounting and now it was time for the true problem.

BREATHIN’ EASY

The airbox. Quite a lot of our R&D was centered on this half within the lead as much as the construct, as we knew it might be the ‘make or break’ for the entire challenge. Yamaha began shifting in direction of the reverse cylinder engine round 2010 with the YZ450F with the WR implementing the identical expertise quickly after. Because of this the exhaust exits from the rear of the cylinder and the air consumption breathes from the entrance, putting the inventory WR airbox up close to the handlebars (the place a standard gas tank can be) as a substitute of on the rear of the bike like most different fashions. The YZ two-stroke engine is the precise reverse, and to make issues worse, the air consumption and carby line up immediately with the rear shock reservoir.

With these components now in place we started working making a one-piece, full aluminium, air field and consumption pipe to marry up the carby with the inventory entrance mounted airbox of the WR. Machined adapters had been made to attach each ends of the air field in place, then we reduce and shut all the pieces in between.

The airbox hugs across the rear spring and makes use of all of the obtainable area doable to get the amount of air that the large bore would want. It’s a singular form, however one which proved to be flawless in testing, which was a bonus.

With the textured black powder coat utilized lots of people are shocked once you inform them it’s a completely aluminium airbox. It appears to mix in properly with the entire construct, once more attempting to maintain the manufacturing unit look alive!

From right here we had been on a roll with what gave the impression to be the large points out of the best way. We modified the radiators to swimsuit the YZ cooling system, fabricated exhaust and enlargement chamber brackets for the brand new Professional Circuit system and set to work becoming the brand new Rtech plastics and OEM equipment, together with a number of trick bits for good measure. Moto Equipment added the ending touches to the physique with a sticker package that completely took the entire challenge to the subsequent stage, tying all the pieces in with an epic manufacturing unit look.

With the principle physique of the bike absolutely assembled it was off to Motolab to tune the suspension and get that large bore energy to the bottom. This was a vital and principally neglected a part of getting the bike to work for, not towards, you, and it was one thing we knew we needed to get proper, particularly with the handful we had been creating! At this level, AP Auto Electrical was additionally performing some wizardry on the inventory wiring loom, taking out the surplus wiring that we didn’t want and integrating the components we did in order that we may hold the inventory sprint, switches, indicators and so on.

With the final elements full we lastly acquired to face again and have a look at the bike as an entire. It was a loopy feeling to lastly stand in entrance of the bike that was only a dream solely months earlier than. It was getting near midnight as we completed bolting the final components on however that wasn’t going to cease us listening to what our exhausting work had created. The bike rolled out of the GJM workshop lastly again on its wheels and with a fast faucet of the button, the WR325 got here to life! Filling the evening air with the candy sound and odor of two-stroke. This second made all these lengthy nights and months of planning abruptly really feel value it.

TESTING TIMES

The subsequent day was testing, and it was positively essentially the most anticipated half. My predominant concern was whether or not the body modifications would change the best way the bike dealt with, in addition to how the brand new engine would carry out at excessive revs with the customized air field. The identical because it had the evening earlier than, a fast faucet of the button and the WR325 was awake and wanting to get after it. All earlier worries had been forgotten as I hit the primary nook and was pleasantly stunned that nothing had modified in the best way of dealing with; nonetheless the identical trusted WR ergonomics railing the nook with ease. Feeling greater than snug already, I wound on the throttle mid-corner and held on for expensive life because the tyres gripped the grime. The ability was clean and broad down low with miles of torque at my fingertips, adopted by a powerband that hit like an absolute freight prepare.

You couldn’t wipe the smile off my face for the remainder of the day. The Yamaha WR325 was all the pieces I had hoped it might be, and it was lastly actuality. The truth that we may make it work, and work so properly is a testomony to everybody concerned on this challenge and I thanks all in your efforts. Now to get the hours on it and actually put it by means of its paces!

The post BIKE BUILD: YAMAHA WR325 TWO-STROKE appeared first on lickscycles.com.

source https://lickscycles.com/bike-build-yamaha-wr325-two-stroke/?utm_source=rss&utm_medium=rss&utm_campaign=bike-build-yamaha-wr325-two-stroke

No comments:

Post a Comment